February 22, 2022

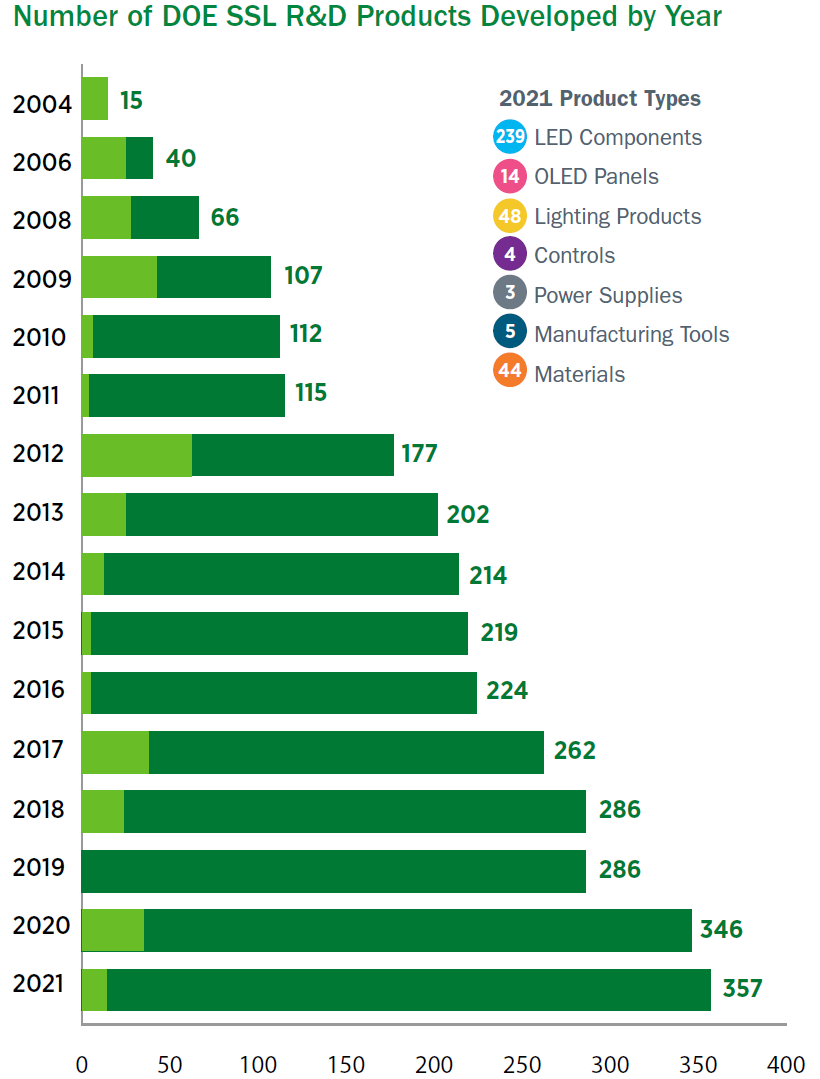

DOE Funds Helped U.S. Firms Launch 357 LED Products

Many advances in Solid-State Lighting commercial product development stem from DOE-funded projects

The U.S. Department of Energy (DOE) began funding solid-state lighting (SSL) R&D in 2000, and to date has supported 347 SSL projects in the areas of applied research, product development, and manufacturing R&D. These projects are funded through the DOE SSL Program and the Small Business Innovation Research (SBIR) Program. This support has directly advanced the scientific understanding and performance of SSL through the publication of articles in technical journals, the creation of intellectual property (with 458 patents submitted), and the direct development of more than 357 commercially available, state-of-the-art products by U.S. companies. Those products—which include lamps, luminaires,

LED components, power supplies, controls, materials, and manufacturing tools—have contributed to about $20 billion in U.S. energy savings so far.

However, the actual impact of the DOE SSL Program is far greater than indicated by those figures, which only include products directly developed or enabled by DOE R&D funding— and don’t include the millions of derivative, influenced, or

next-generation products that are based on projects that received direct DOE support. In many instances, DOE funding led to the development of widely used product platforms, or to materials that have gained widespread adoption, and are now found in tens of thousands of specific products, with millions of individual units sold. Likewise, DOE-funded improvements to production tools have increased product consistency, quality, and yield and have led to cost reductions in LED lighting components and products worldwide.

LED Components

LED components are at the heart of LED-based SSL technology, because they generate the light. Developing and producing advanced LED components has been a strength of U.S. LED manufacturers, particularly Cree and Lumileds. DOE SSL R&D to date has supported the development of 239 commercially available LED component products—which doesn’t include follow-on products based on the original technology developed. Thus, DOE funding has actually influenced multiple generations of state-of-the-art LED component products, which typically exhibit advancements in efficiency, cost, integration, and performance. These advancements have come about through the rapid application and commercialization of new scientific understanding of LED materials and device structures—and improvements continue to come at a rapid pace.

The DOE SSL Program has supported a number of projects in which LED chip and package development led to the creation of a product platform used in successive generations of industry- leading LED package products, enabling vast amounts of energysavings. An example is the development of the Cree EZBright® LED chip architecture, which enabled nearly a doubling in efficiency compared to the previous best Cree chip type (also supported by DOE funding) and proliferated into multiple LED package architectures, including the XLamp®, XR-C, XR-E, XP, MC, MT, and XM. These packages can be found in many Cree lighting products, including replacement lamps (e.g., LBR-30), downlights (e.g., CR-4™ and LR-6™), troffers (e.g., CR-22™), and canopy lights (e.g., the 227, 228, and 304 series). The Cree chip and package products are also used by Cree customers in vast numbers of lighting products.

The DOE SSL Program has supported a number of projects in which LED chip and package development led to the creation of a product platform used in successive generations of industry- leading LED package products, enabling vast amounts of energysavings. An example is the development of the Cree EZBright® LED chip architecture, which enabled nearly a doubling in efficiency compared to the previous best Cree chip type (also supported by DOE funding) and proliferated into multiple LED package architectures, including the XLamp®, XR-C, XR-E, XP, MC, MT, and XM. These packages can be found in many Cree lighting products, including replacement lamps (e.g., LBR-30), downlights (e.g., CR-4™ and LR-6™), troffers (e.g., CR-22™), and canopy lights (e.g., the 227, 228, and 304 series). The Cree chip and package products are also used by Cree customers in vast numbers of lighting products.

Another LED package platform developed with DOE R&D support involves the use of patterned sapphire substrates (PSS) by Lumileds. This important development has enabled increased efficiency and light output at low cost, and has been so effective that Lumileds has transitioned most of its LED component products to PSS architecture. More recently, the DOE-funded R&D focus on understanding the physical mechanisms of droop—the reduction in efficiency at higher current densities— has led to dramatic performance advancements for Lumileds’ cyan and green LEDs. These LEDs can be used in color-tunable lighting products for horticulture or lighting that is tailored for human physiological responses. Advancements in these colored LEDs are also critical for transitioning to direct emitter (no phosphor) lighting architectures to achieve the ultimate efficacy potential for LED lighting. A recent DOE-funded R&D project at Lumileds explored efficacy improvement at high brightness operating conditions. Efficiency advancements were researched in the epitaxy, phosphor, light extraction, and package architecture. Advancements from this R&D were quickly commercialized into new LED package products.

The Cree and Lumileds LED platforms, used in many millions of energy-saving lighting products, have been critical to LED lighting’s success. And Cree, Lumileds, and other manufacturers continue to improve these platforms even further. DOE supports research to improve LED performance at all wavelengths and the development of downconverter materials into LED packages to more effectively match the human eye response and increase efficacy. These are just two examples of the improvements that can still be achieved to continue the advancement of LED lighting technology.

OLED Panels

OLED panels are at the heart of OLED-based SSL. OLED panels contain the organic emitters, organic charge transfer layers, light extraction technologies, and encapsulation—all of which enable the OLED to efficiently and reliably generate light. Similar to LED packages, OLED panels can be integrated into the ultimate lighting product by integrating the panel with a power supply, the mechanical structure, and secondary optics, if necessary. The DOE SSL Program has invested in numerous OLED R&D projects resulting in new understanding, patent generation, and new manufacturing technologies. OLEDs and LEDs are complementary lighting technologies, i.e., while LEDs are small and bright and require engineering to reduce glare, OLEDs are large and emit diffuse light.

OLEDWorks, an OLED panel manufacturer based in Rochester, New York, has commercialized 14 products based on DOE SSL R&D funding. The Brite 3 family of products alone includes 12 different products with different shapes, color temperatures, and finishes. In that R&D project, OLEDWorks explored new light extraction architectures, new organic stack configurations, and new encapsulation schemes necessary for a commercially feasible lighting product. Taken together, the advancements from that R&D resulted in a 33% improvement in efficacy over the state of the art, with good light quality and reliability.

Lighting Products

DOE SSL R&D funding has led to the direct development of 48 commercially available lighting products. With GE Lighting, DOE funding was focused on the development of an advanced red phosphor material. GE Lighting decided to use the phosphor material internally on their own products, and the benefits were quickly realized through the development of a whole family of energy-efficient GE Lighting products that are now on the market. The phosphor that was developed with DOE R&D funding is now an essential part of the technology platform for GE high color quality and high efficiency lighting products.

Through an alternative R&D funding approach, the L Prize® competition, DOE supported the development of the Philips L Prize-winning lamp, which was submitted in 2009. Still widely regarded as the best general-purpose light bulb ever made, this

A-lamp has high efficacy (>90 lm/W), long life (>25,000 hours), near-perfect color stability, excellent color quality, excellent light distribution, and high light output. The early development of the L Prize lamp directly enabled Philips to rapidly develop a family of energy-saving products based on what they had learned, and the basic lamp design has been used in numerous subsequent products, including the color-tunable Hue lamp.

The DOE SSL Program has also funded a handful of additional R&D projects that have not yet directly led to commercialized products. Some of these project concepts are still being developed and may yield products in the future, and some have led to alternative concepts that led to products—which happened with Cree, Philips, OSRAM, and Color Kinetics. Although these indirectly influenced products are not included in this analysis, they nevertheless are an important part of the total impact of DOE R&D funding. For example, specialized LED lighting concepts for classrooms, hospital rooms, and offices were developed to take advantage of the spectral control offered by LED technology. These concepts are designed to engage human physiological responses for improved hospital patient recovery in the hospital and improved focus and visual comfort in the classroom and office.

The RTI/Finelite R&D project “Luminaires for Advanced Lighting in Education” developed and validated technology for use in educational settings. This project concluded in 2019. As part of the subsequent commercialization process for the LED classroom product line, RTI/Finelite developed 32 white-tunable luminaires that can be tuned between cool white and warm white settings to elicit physiological and behavioral responses from students. The lights can also be dimmed to 1% of their maximum output.

Controls

The RTI/Finelite classroom project resulted in the development of a full suite of luminaires and controls that enable adjustment of the color from the luminaires. Four controls products were developed, including a control app, two control packs, and a control station.

Power Supplies

Another important component of LED lighting products is the power supply. LEDs typically require power conversion from 120V AC to low-voltage DC, which affects the total efficiency of the system. The DOE SSL Program supported a Philips Lighting project to develop an efficient, small-form-factor, long-lifetime family of LED power supplies, which directly resulted in the development of three commercially available products and four derivative products (the latter not counted in this analysis). These low-cost products exhibit high conversion efficiency (>90%), long life (>50,000 hours), and compact form factor.

Manufacturing Tools

So far, DOE R&D support has resulted in the development and commercialization of five manufacturing products that, collectively, have been used to produce billions of LED chips. DOE funding directly enabled Veeco’s development of three specific product features that can be used with the company’s state-of-the-art metal organic chemical vapor deposition (MOCVD) tools to produce LED wafers. These tools, sold worldwide, produce hundreds of millions of LEDs each year, and their advancements have led to improved control, uniformity, yield, throughput, and cost of ownership. Although Veeco’s

DOE-supported work has ended, the company continues to develop several of the original concepts. These tools are used by nearly every LED manufacturer to generate vast quantities of LED chips that are used in every type of LED lighting.

Ultratech and KLA-Tencor have also developed manufacturing tools with the help of DOE R&D funding. Ultratech developed a low-cost lithography tool for manufacturing high- brightness LEDs—a high-value tool that has been sold to LED manufacturers worldwide. Likewise, DOE R&D support enabled KLA-Tencor to develop an inspection tool for monitoring incoming sapphire substrates to reduce defective parts and increase yield. This, too, is a high-value tool and has been sold worldwide.

The manufacturing tools developed with the help of DOE R&D support have already produced hundreds of millions to billions of LED chips that are used in LED lighting products. The improved performance and reduced cost of these LEDs has accelerated adoption and increased total energy savings.

Materials

DOE R&D funding support has led to the development of 44 commercially available materials used in the manufacture of LED packages and lighting products. The DOE SSL Program funded an R&D project with Lightscape Materials that resulted in the development of two phosphor products that are used as downconverters in LED packages. Lightscape developed novel nitride- and oxynitride-based phosphor downconverters that have excellent conversion efficiency as well as thermal stability to maintain the color point of the LED package. Almost all LED packages use phosphors to create white light, so improvements in phosphor efficiency and performance have a large impact on the LED package efficiency and resulting luminaire or lamp efficiency. Thermal stability is often a shortcoming in phosphors, which leads to noticeable color shift as the LED or lighting product is operated at different temperatures.

The Lightscape products could simultaneously achieve good conversion efficiency and color stability, making them a compelling option for LED component integrators. Lightscape Materials was eventually acquired by Dow Chemical and the developed phosphors are now part of the Dow Chemical product line.

The DOE SSL Program also supported WhiteOptics’ development of a low-cost, stable, highly reflective diffuse coating material that maximizes the optical efficiency of LED luminaires while reducing glare. This robust material maintains its optical performance even at elevated temperatures and over long periods of time (>50,000 hours). Even a small improvement in the reflectivity of an optical coating can dramatically improve the optical efficiency of a luminaire, since multiple reflections are often required before the light exits. The WhiteOptics coating is 98% reflective, which means that the light output only diminishes by 2% with each “bounce”—whereas, for example, it diminishes by 10% per bounce with white paint, which typically is 90% reflective.

DOE R&D funding also supported the development of another optical element. In a DOE SBIR project, Lucent developed a thin, flexible optical waveguide and a light engine designed to work with their waveguide. The waveguide couples bright light generated by an array of LEDs with a thin plastic sheet that then emits the light over a large area, reducing glare and controlling the optical distribution of the light. The Lucent waveguide technology can be made into almost any size and can be thinner than the size of the LEDs, enabling thin and flexible lighting products.

For OLEDs, light trapped within the organic semiconductor layers directly limits efficiency which, in turn, limits lifetime, brightness, and cost of OLED devices. With DOE R&D support, Pixelligent, in Baltimore, Maryland, has developed and commercialized low-cost, organic, optical extraction materials with scattering nanoparticles to improve light extraction of OLED devices.

Conclusion

While DOE provides R&D funding support, the real credit for the resulting products belongs to the researchers and product developers themselves. SSL science and technology is rapidly moving forward, and there are still significant opportunities to develop improved manufacturing tools, LED components, materials, power supplies, lighting products, and more—which can increase and accelerate the energy savings potential of SSL. In addition, improved understanding of the underlying science of the application of lighting, including human physiological responses to light, will enable optimized products that can do the lighting job as effectively and efficiently as possible. DOE continues to identify and support those R&D projects in areas of fundamental understanding, product concepts, and advanced manufacturing that offer the highest potential energy savings impact.

SOURCE: U.S. Departent of Energy. For more information, visit: energy.gov/eere/ssl/

Don’t miss the next big lighting story…Click here to subscribe to the inside.lighting InfoLetter |