March 27, 2024

Innovation Meets Sustainability:

Intek Plastics Unveils New Bioplastic Composite Extrusion Materials

HASTINGS, Minn. — Intek Plastics, a leading provider of plastic extruded components for diverse applications, proudly announces the launch of three innovative and sustainable biocomposite plastic materials. Focused on reducing environmental impact while delivering superior performance, Intek’s new materials offer a compelling solution for businesses seeking more sustainable alternatives without compromising aesthetics or functionality.

Reduced-Carbon-Offset Materials

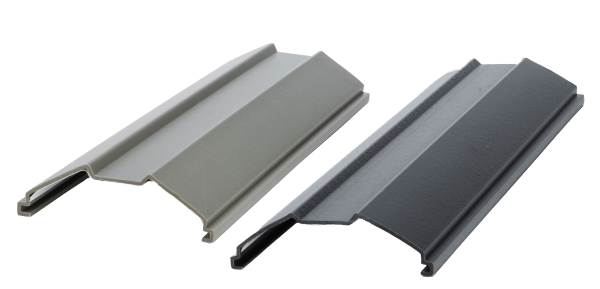

Intek’s revolutionary biocomposite contains 10% to 20% UBQ™ upcycled municipal waste, combined with traditional or recycled ABS for enhanced sustainability. Available in standard gray/green or custom colors, these material formulations offer performance and durability. Moreover, they can be co- or tri-extruded, ensuring versatility across a wide range of applications, such as lighting fixtures, hydroponic channels, window and door components and extrusions for other products.

Intek’s revolutionary biocomposite contains 10% to 20% UBQ™ upcycled municipal waste, combined with traditional or recycled ABS for enhanced sustainability. Available in standard gray/green or custom colors, these material formulations offer performance and durability. Moreover, they can be co- or tri-extruded, ensuring versatility across a wide range of applications, such as lighting fixtures, hydroponic channels, window and door components and extrusions for other products.

Wood Biocomposite (in Formulation and Validation)

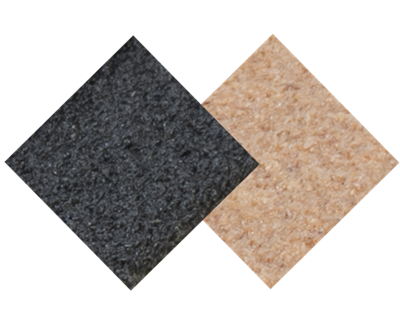

Offering a unique textured aesthetic, Intek is developing and validating a wood biocomposite material. This formulation combines wood byproducts with recycled polyolefins, providing visual appeal and environmental benefits. Additional filler materials such as hemp, oats and wood flours are being researched and tested. Biobased and/or biodegradable carriers are currently in development for even greater sustainability and versatility.

Offering a unique textured aesthetic, Intek is developing and validating a wood biocomposite material. This formulation combines wood byproducts with recycled polyolefins, providing visual appeal and environmental benefits. Additional filler materials such as hemp, oats and wood flours are being researched and tested. Biobased and/or biodegradable carriers are currently in development for even greater sustainability and versatility.

Glucose-Based Bioplastic

A transparent bioplastic, Intek’s innovative transparent materials are derived from starch and have excellent optical properties, with over 92% light transmission. This biocomposite is developed mainly from plant-based isosorbide. BPA-free, it combines the advantages of polycarbonate (PC) and polymethacrylate (PMMA). With superb impact and scratch resistance, this line of materials is ideally suited for diffusers, optical lenses and greenhouse panels. Certified by the USDA BioPreferred Program, these materials adhere to stringent sustainability standards, reflecting Intek Plastics’ commitment to environmental stewardship.

A transparent bioplastic, Intek’s innovative transparent materials are derived from starch and have excellent optical properties, with over 92% light transmission. This biocomposite is developed mainly from plant-based isosorbide. BPA-free, it combines the advantages of polycarbonate (PC) and polymethacrylate (PMMA). With superb impact and scratch resistance, this line of materials is ideally suited for diffusers, optical lenses and greenhouse panels. Certified by the USDA BioPreferred Program, these materials adhere to stringent sustainability standards, reflecting Intek Plastics’ commitment to environmental stewardship.

“Our new bioplastic composite extrusion materials represent a significant milestone in our commitment to sustainability and innovation,” says Kevin Hogan, CEO of Intek Plastics. “By offering eco-friendly alternatives without compromising performance or aesthetics, we empower our customers to make environmentally responsible choices while gaining a competitive edge in the market.”

For more information or to inquire about these sustainable materials, visit Intek Plastics’ website at www.intekplastics.com or call 651-437-7700.

Intek is committed to collaborating with customers to revolutionize products with cutting-edge extrusion solutions. The company’s skilled engineers work closely with customers to recommend the perfect materials and provide engineering assistance, ensuring that custom extruded components conform to precise standards.

About UBQ Materials Ltd.

UBQ Materials Ltd. closes the loop between the ecosystems of waste and materials. Through its advanced conversion technology, UBQ Materials has created a pioneering bio-based thermoplastic, UBQ™, made entirely from residual waste, including all organics and hard-to-recycle materials. A sustainable plastic substitute, UBQ preserves finite resources, diverts waste from landfills and incinerators and prevents emissions. A certified B Corp, UBQ Materials is expanding globally to provide the world’s largest businesses, municipalities and consumers with a climate-positive solution for a circular economy. Learn more by visiting www.ubqmaterials.com.

About Intek Plastics

Intek Plastics is a leading North American manufacturer that delivers engineered thermoplastic extrusions, fabricated sub-assemblies and value-added services to original equipment manufacturers. Headquartered in Hastings, Minnesota, with a second facility in Medford, Wisconsin, the company is a best-in-class partner with the largest customers in the fenestration industry. Additionally, Intek provides plastic extruded solutions to the construction, lighting, refrigeration, agriculture, recreation, appliances and transportation markets.

When collaborating with Intek Plastics’ team of experts, customers get more than high-quality extruded components; they gain a competitive edge. The Intek team is committed to collaborating with customers to revolutionize products with cutting-edge extrusion innovations. Intek Plastics’ vision is to become one of the largest and most respected plastics companies in the world. With an eye to the future, the company invests heavily in strategic acquisitions, innovative materials, new processes and progressive technologies to meet its customers’ needs. www.intekplastics.com

Don’t miss the next big lighting story…Click here to subscribe to the Inside Lighting InfoLetter |