September 26, 2023

DOE Reveals Inaccurate Claims in GUV Lighting Products

Photo credits: U.S. Department of Energy

"Problematic" concerns raised in 8 of 13 germicidal ultraviolet lighting products tested

The U.S. Department of Energy (DOE) has unveiled its initial set of test results for germicidal ultraviolet, or GUV, products. These findings underscore the potential for significant energy savings but also emphasize the need to address product performance claims.

Regarded as a powerhouse in the battle against airborne diseases, GUV disinfection technology stands out for its effectiveness and energy efficiency. Its importance is underscored by the new building design guidelines laid down by groups like the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) and the Centers for Disease Control and Prevention (CDC).

Low-pressure mercury technologies, long a staple in healthcare and institutional settings, dominate the GUV landscape. However, newer alternatives, such as UV-emitting LEDs and krypton-chloride-based excimer lamps, are emerging. But there's a catch: voices from industry groups, researchers, and consumer advocates have raised concerns that some GUV offerings might not live up to their performance promises. This report is the DOE’s answer to those concerns.

The CALiPER Test

For those familiar with the 2006-launched Commercially Available LED Product Evaluation and Reporting (CALiPER) program, this new assessment will feel familiar. That program came to life to provide trusted insights on the performance of LED lighting products as they began lighting up the market. By utilizing commercial test labs to test actual products, the program assessed how products stacked up against their claims and compared to other lighting technologies. These findings serve as a knowledge base for various stakeholders, promoting claims grounded in industry-standard testing protocols.

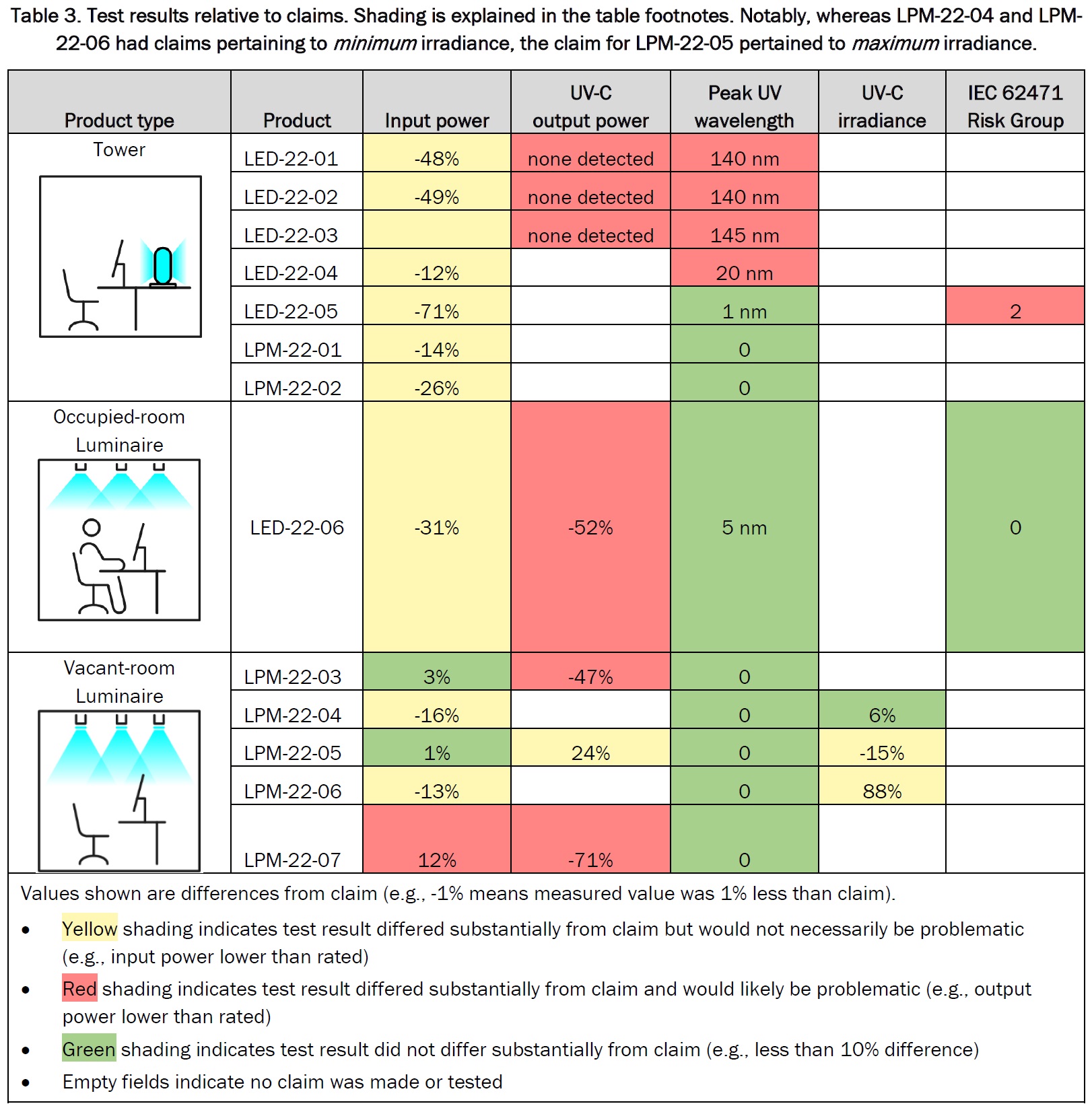

In its GUV product analysis, the DOE examined several categories: seven portable towers (of which five are LED and two low-pressure mercury), one LED luminaire designed for occupied rooms, and five luminaires meant for vacant rooms (all based on low-pressure mercury technology).

Source: U.S. Department of Energy

Key Insights from CALiPER's GUV Testing

Specifiers and buyers of GUV technology need complete and accurate performance data for the safe and effective application of the technology. Product developers need industry-standard test methods and associated laboratory capabilities to provide this data. This initial round of CALiPER GUV product testing identified a host of issues to be addressed to realize both outcomes. Key issues identified from this initial round of GUV testing include:

-

Incomplete or inaccurate performance claims – Performance claims for products were often absent, untestable (e.g., irradiance without stated distance), contradictory (e.g., unexplained differences between multiple power values), or ambiguous (e.g., unclear whether input power or output power). Measurement units frequently conflicted with quantities, making the intended meaning of the claim All five of the consumer-oriented LED tower products claimed to emit UV-C, but three of them emitted none, and the other two mostly emitted UV-A. Eight of the thirteen fixtures tested resulted in at least one test result differing substantially from data claimed by the manufacturer that would likely be problematic.

-

Potential for unsafe products – Products with relatively little UV-C radiant intensity can still exceed photobiological safety The user manual for one LED tower warned users to stay at least 1 m away from the product, but IEC 62471 testing for Actinic UV and Near UV hazards indicated that more than 2.5 hours of exposure to the product at that distance would be unsafe, corresponding to an RG-2 (Medium Risk) classification. The same product was found to emit UV-C before its remote control was used to switch it on, potentially posing a safety hazard to room occupants who believe it is off.

-

Energy efficiency opportunities – There was a wide variation in UV-C radiant efficiency, from 04% for the lowest-output UV-C emitting LED product (the whole-room luminaire for occupied rooms), to 42% for the highest-output LPM product (a 2x4 troffer for vacant rooms). LPM products with white louvers or reflectors had substantially lower UV-C radiant efficiency than those with only specular reflectors. These results indicate a substantial opportunity for more energy efficient product designs.

-

Long-term performance of UV-C LEDs – Of the two UV-C LED products tested long-term, one had a two-year warranty (implying a rated life of at least 17,520 h) but dropped to 66% of its initial output at 500 The other, which claimed a lifetime of about one year in continuous use (8,760 h) dropped to 85% at 500 h. These findings suggest rated lifetimes for UV-C LED products may merit close scrutiny.

-

Testing challenges with larger dimension GUV products – UV-C radiant intensity data was gathered for all products, but the product-detector distance of the goniometer was limited because the mirror that is typically used to increase test distance could not be used for UV-C. Consequently, the data collected for larger dimension products (comprising all the LPM products) was near-field (i.e., not true far-field intensity), and thus cannot be reliably used to calculate irradiance via the inverse-square law as is typically accomplished through design It is unclear if this is an industry wide testing limitation and what solutions may address it.

-

Test differences between integrating sphere and goniometer testing – Significant discrepancies were observed between integrating sphere and goniometer test results. For the limited scenarios where comparisons were possible, integrating hemisphere measurements of UV-C radiant flux were around 25% lower than values based on goniometer testing. In one scenario, a unit tested both ways exhibited a 24% discrepancy. In another scenario, two models each had units dedicated to each kind of test (which may differ due to manufacturing tolerances), and they exhibited discrepancies of 26% and 31%. Integrating-sphere testing was limited to the two UV-C emitting products suitable for measurement in the available 20-inch diameter hemisphere. Larger integrating spheres suitable for GUV product testing would enable measurement of larger GUV products as well as comparisons with goniometer measurements. However, larger spheres may not be available at commercial test laboratories.

With the specific products tested in this round, the results demonstrate an important need for further education, industry standards, and accountability in the GUV product industry. Though it is possible some product developers were intentional in communicating inaccurate performance claims, the preponderance of incomplete, ambiguous, contradictory, and untestable claims with incorrect units suggests that some product developers and sellers may not understand GUV technology or how to measure and accurately report product performance. To address this issue, the industry could prioritize development of a standard set of recommended testing for each product type, with a standard set of associated performance data that should be reported for each product. Once developed, product developers, sellers, specifiers, and buyers could be educated about its use.

The results also demonstrate that there is extremely wide variation in radiometric performance among different GUV product types and technologies, with this round of testing showing LED products at orders of magnitude lower UV-C radiant efficiency than LPM products. However, the application performance and efficiency of GUV must also consider spectrum and intensity distribution to determine germicidal efficacy. As GUV technology continues to evolve, there is a need to evaluate different GUV product types, technologies, spectrums, intensity distributions, and design approaches to identify those that are most energy efficient and effective in specific applications.

Finally, the results demonstrate there is more work needed to address testing limitations and improve testing laboratory infrastructure and capabilities to support the accurate testing of GUV products. In particular, the ability to test larger-dimension GUV products is needed, to enable the accurate use of GUV application design software using electronic files that contain far-field UV-C radiant intensity data. Efforts are also needed to evaluate and understand discrepancies identified between results from integrating sphere and goniometer testing.

NOTE: A prior version of this article incorrectly reported 7 of 13, not 8 of 13, germicidal ultraviolet lighting products tested. We regret the mistake.