May 20, 2024

Investigating the Purple Light Phenomenon in LED Streetlights

Researchers test 28 samples and report the technical causes of LED streetlight color shift

In recent years, from Boston to Billings and from Winnipeg to Winston-Salem, communities across the United States and parts of Canada have reported a peculiar phenomenon: streetlights emitting purple light. This unusual color shift has garnered widespread attention, with numerous local news stations and newspapers reporting the events including a brief explanation of the cause. While some reports capture the LED phosphor degradation issue in a general sense, other reports often attribute the issue to faulty "LED bulbs," an inaccurate simplification that fails to capture the underlying technical reasons.

Former IES Conference keynoter Adam Rogers wrote a 2022 article in Business Insider called “The Great Purpling: Why Faulty Streetlights Are Turning Cities Purple.” Longtime lighting people might remember that Rogers authored the cult favorite article “The Science of Why No One Agrees on the Color of This Dress.” Additionally, Scientific American detailed the technical issues in its 2023 article “Streetlights Are Mysteriously Turning Purple. Here’s Why.”

Researchers Recently Tested Failed LED Modules

Recognizing the newsworthiness and technical nuances of this topic, the Raleigh Section of the Illuminating Engineering Society (IES) hosted a webinar on May 10 titled "Causes of Excess Color Changes in Streetlights." The presentation, authored by the LED Systems Reliability Consortium (LSRC), provided a comprehensive examination of the factors leading to the widespread color change. The consortium's experts, including independent consultant J. Lynn Davis, Steve Paolini of Telelumen, LLC, Morgan Pattison of Solid State Lighting Services, Inc., and Troy Trottier of Trottier Consulting, LLC, delved into the scientific details of this phenomenon. Dr. Davis, the main presenter, is expected to further discuss this topic at the IES Street and Area Light Conference in Atlanta, Georgia, in September.

Above: Excerpt from IES Raliegh Section webinar, Causes of Excess Color Changes in Streetlights

The LSRC's investigation highlighted the technical specifics behind the purple streetlights, focusing on a particular type of LED used in the affected streetlights: the chip-scale package (CSP) LED chip. These LEDs are designed with a chip-sized silicone phosphor layer adhered to the top surface of the LED chip. The silicone phosphor layer converts the blue light emitted by the LED chip into the white light typically expected from streetlights.

Failure occurs at the LED component level

The cause of the white light to purple light failure pinpointed by the LSRC occurred in this phosphor-silicone layer. Over time, the silicone failed to maintain its adhesion to the LED chip, leading to significant changes in the light's color output. This adhesion failure resulted in cracks and delamination, where the phosphor layer detached from the LED chip. Without this layer, the LEDs emitted a blue or purple light instead of the intended white light.

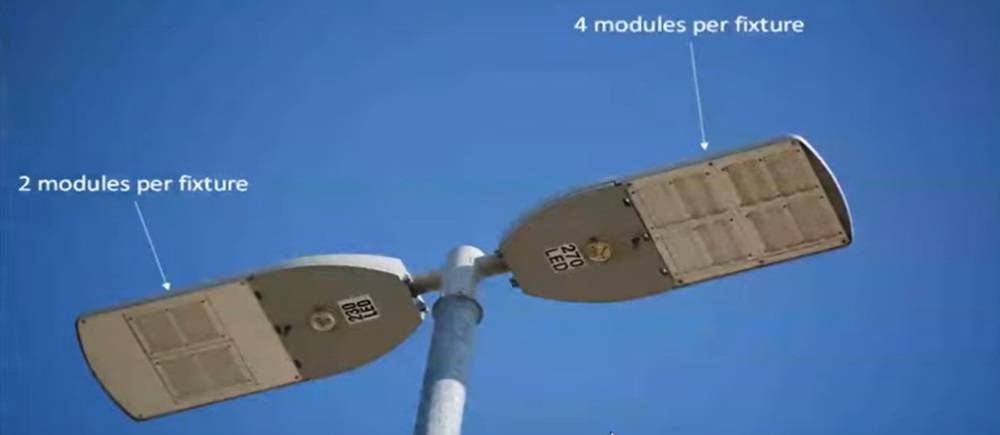

The LSRC conducted a detailed evaluation of 28 LED modules, which were warranty replacements received from the North Carolina Department of Transportation. These devices, installed around 2018, were extracted after several years of operation due to noticeable discoloration. The samples included LED modules from various streetlights, with each module containing 20 CSP LEDs. By analyzing these samples, the LSRC was able to identify the specific failure mechanisms leading to the purple discoloration observed in the field.

The Testing

The LSRC conducted a comprehensive evaluation of the affected LED modules to uncover the root causes of the purple discoloration. This involved a series of detailed inspections and tests on the CSP LEDs.

|

|

Above: Different LED modules with varying failures among the 20 LEDs in each module. |

Physical Inspection

-

Each module was visually inspected to assess the condition of the LEDs and any apparent physical damages.

Photometric Testing

-

Photometric tests were performed to measure light output and color. This included assessing the spectral power distribution—how the light's intensity is distributed across different wavelengths.

Identification of Issues

-

Observing Color Shifts: Specific modules showed significant shifts toward the purple spectrum. The intensity of the blue peak increased while the phosphor emission decreased, contributing to the color shift.

-

Comparison Across Samples: The gradual progression of color points from near-standard (white light) to heavily shifted (blue/purple) was mapped, illustrating the degradation over time.

Thermal and Material Analysis

-

Thermal Imaging: Thermal imaging was used to determine if overheating contributed to the failures. It revealed that heat was likely not a significant factor, as the radiant power of the devices was increasing, indicating that the blue LEDs were still highly active.

-

Chemical and Material Inspection: The silicone phosphor layers were examined for signs of cracks or complete delamination, directly influencing the color shifts observed. The analysis included checking for brittleness or other material failures that could lead to phosphor degradation.

Further Analysis of Delamination and Cracking

-

Microscopic Examination: Additional examination involved taking the fixtures apart to observe the condition of the phosphor layer more closely. Evidence of phosphor layer cracking was found, through which blue light could pass unconverted, exacerbating the color shift to purple.

Overall Assessment

-

Assessment of LED Condition: The researchers concluded that the silicone phosphor layer's integrity was compromised over time due to material failures. This led to increased blue light emission and a decrease in overall light quality.

This thorough examination and analysis process helped the researchers understand the technical reasons behind the color shift in streetlights, focusing on material integrity and operational longevity of the LED modules.

Detailed Research Findings:

The LSRC identified the root causes of excessive color changes in streetlights, particularly the shift toward a royal blue color point. Here's a detailed explanation based on their findings:

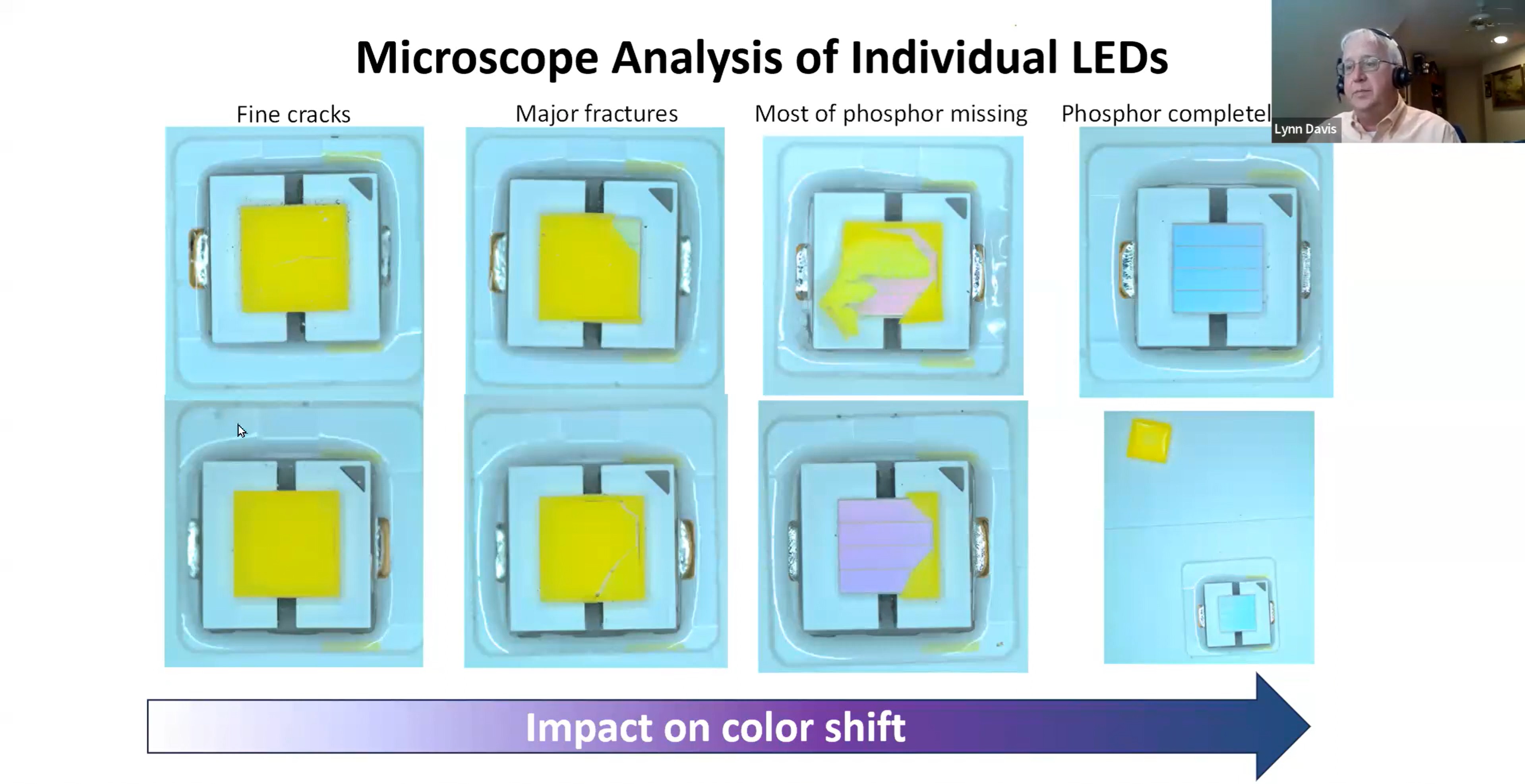

Above: Excerpt from IES Raliegh Section webinar, Causes of Excess Color Changes in Streetlights

Fine Cracks in the Silicone-Phosphor Layer: The LSRC found that fine cracks develop in the silicone-phosphor layer of LEDs exhibiting an excess blue color shift. These cracks, which form top-to-bottom in individual LED packages, grow during operation. This gradual growth leads to a cumulative effect at the module or fixture level, shifting the color point of the entire LED module toward the royal blue spectrum. Since the light emitted from each LED is mixed at the fixture level to illuminate targets, even a few affected LEDs can alter the overall light color emitted.

Varying Impact Across LEDs: While all LEDs within a module may be subjected to similar conditions, the extent to which each LED is affected can vary. Some LEDs might show minimal or no signs of degradation, while others might fail catastrophically. This variance affects the uniformity of light output and color rendering across the module.

Adhesion Issues Between LED Chip and Silicone-Phosphor Layer: Over time, the adhesion between the LED chip and the silicone-phosphor layer deteriorates. This deterioration is marked by the silicone binder becoming brittle, which can lead to delamination (the separation of the silicone-phosphor layer from the LED). Visual evidence of such damage includes observable cracks and, in severe cases, gross fractures. When the phosphor layer is completely missing or separated, the LED emits only blue light, not the broad spectrum of white light for which it was designed.

Consequences of Complete Separation: In instances where the silicone-phosphor layer is entirely absent from the LED package, the blue light from the LED does not undergo conversion by the phosphor. This lack of conversion means that there is no broad spectrum creation, leading to a significant reduction in both lumens (light output) and color quality. The result is a light that not only appears bluer but also fails to meet the intended luminous efficacy and color rendering requirements.

The Commercial Side of the Story:

As Dr. James presented the LSRC research findings, he was careful not to mention the names of any component or fixture manufacturers. In a one-on-one follow-up with Inside Lighting, Dr. James continued to be agnostic and clarified that only one manufacturer's fixtures were the source of all 28 fixtures provided by the North Carolina Department of Transportation (NC DOT) and tested.

Inside Lighting believes the manufacturer was Acuity Brands, though it should be emphasized that these failures occurred at the LED component level. Acuity Brands does not manufacture LED chip-scale packages and sources such components from its LED vendors. The presentation further indicated that "several fixture manufacturers may be affected."

When asked if he had any clarity on the failure rates of fixtures in North Carolina and whether the peak number of failures might be behind us, Dr. James could not provide insights into the matter.

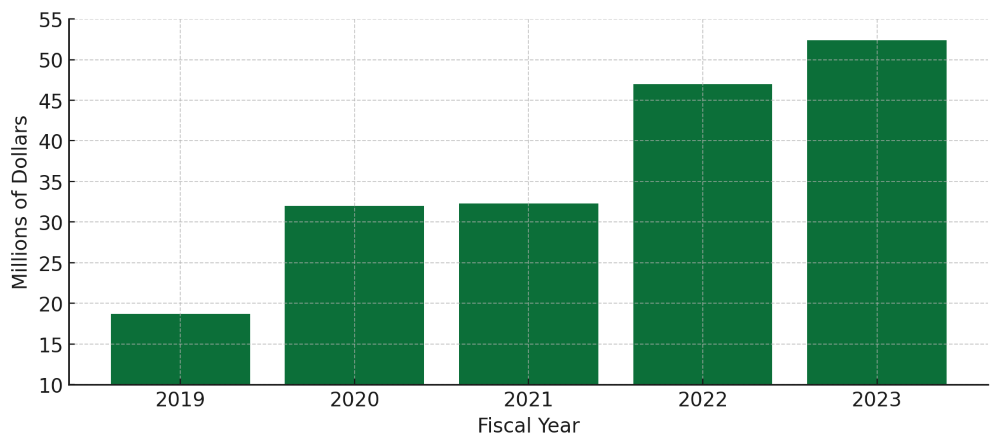

Acuity Brands Warranty Costs Accelerate

Numerous mainstream media reports in the U.S. and Canada cite American Electric Lighting (AEL) fixtures as being involved in these failures across various markets. AEL is a brand of Acuity Brands, the $4 billion North American lighting leader. These streetlight failures have seemingly contributed to a significant uptick in warranty costs in recent years for Acuity Brands.

In 2021, Acuity Brands incurred $32.3 million in warranty and recall expenses. This figure surged to $47.0 million in 2022 and further increased to $52.4 million in 2023. Inside Lighting links this uptick in warranty costs to a widespread issue with purple streetlights.

Above: Acuity Brands warranty costs have risen considerably in recent years.

Additionally, a dispute with a vendor has been brewing behind the scenes in recent years. On October 4, 2023 Acuity Brands' CFO Karen Holcom disclosed that the company recorded a "$13 million pre-tax non-cash charge for the impairment of a receivable based on its collectability." This receivable, as Holcom explained, is from a supplier who owes warranty obligations to Acuity Brands. These obligations are tied to recovery of quality costs incurred for certain ABL outdoor lighting products manufactured and sold between 2017 and 2019.

Numerous messages from Inside Lighting to an Asian LED components manufacturer were ignored after an initial promise to reply to our inquiry about the $13 million dispute with Acuity Brands.

In statements to various mainstream media, Acuity Brands emphasized that Acuity Brands is not the only lighting manufacturer that has experienced this issue.

Safety Concerns

The LSRC concluded that safety concerns associated with the shift in streetlight color due to deteriorating LED components are noteworthy. Streetlights serve not only to illuminate roads and pathways but also to ensure the safety of pedestrians, cyclists, and drivers at night.

When the LED modules emit an unintended purple hue due to the degradation of the silicone-phosphor layer, it can drastically alter the visual perception of the environment. Such changes can lead to poorer visibility, making it difficult for individuals to recognize obstacles, read signs, or accurately discern the colors of traffic signals, which are critical for making safe decisions while navigating. Furthermore, the unexpected color shift can possibly be distracting or even disorienting.

LSRC Recommendations

The LSRC recommends that streetlight makers adopt stringent guidelines for selecting LM-80-15 datasets for LED fixtures to prevent future occurrences of premature LED degradation. Specifically, he advises that the operational current and temperature of the LEDs tested in the LM-80 report should be equal to or exceed those of the actual fixture conditions. This approach ensures that the test conditions accurately reflect the operational stresses that the LEDs will encounter in real-world applications, thereby providing a more reliable indication of their long-term performance and stability.

The LSRC also stresses the importance of utilizing the most extensive possible LM-80 data—over 6,000 hours—to accurately assess LED performance under aggressive conditions surpassing the fixture’s standard operational ratings for current and temperature. This method, coupled with tools that monitor changes in luminous flux and color stability over time, ensures a comprehensive evaluation of the LEDs’ long-term reliability and effectiveness in real-world applications. By adhering to these guidelines, fixture designers can better predict the longevity and color consistency of LEDs, minimizing the risk of premature failure.

The research undertaken by the LED Systems Reliability Consortium (LSRC) has provided an important understanding of the specific failures causing the widespread purple discoloration of LED streetlights. By examining and testing 28 LED modules, the team has unraveled the technical and material issues at play, especially the degradation of the silicone-phosphor layer in CSP LEDs. This work not only contributes to the broader knowledge base of LED technology but also paves the way for future improvements in street and area lighting systems.

Looking ahead, the insights from this research is expected to be further discussed by Dr. J. Lynn Davis at the upcoming IES Street and Area Light Conference in Atlanta, Georgia.