LED Fixture Reliability: Color Shift

The U.S. Department of Energy publishes report that explores the impact of LED color shift over time.

If you are visiting this website, you are likely a lighting professional. You are familiar with terms like LM80, CCT, LPW and other exciting lighting industry acronyms. You are involved in lighting in some way, that ultimately causes an end user -- the ultimate customer, who may not be an astute lighting expert -- to end up with a lighting solution in which you may have been involved in some way.

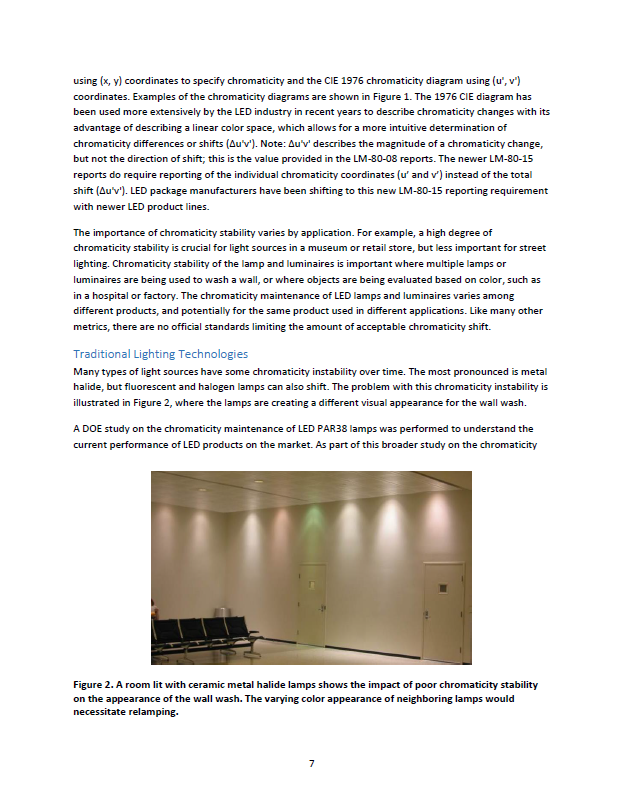

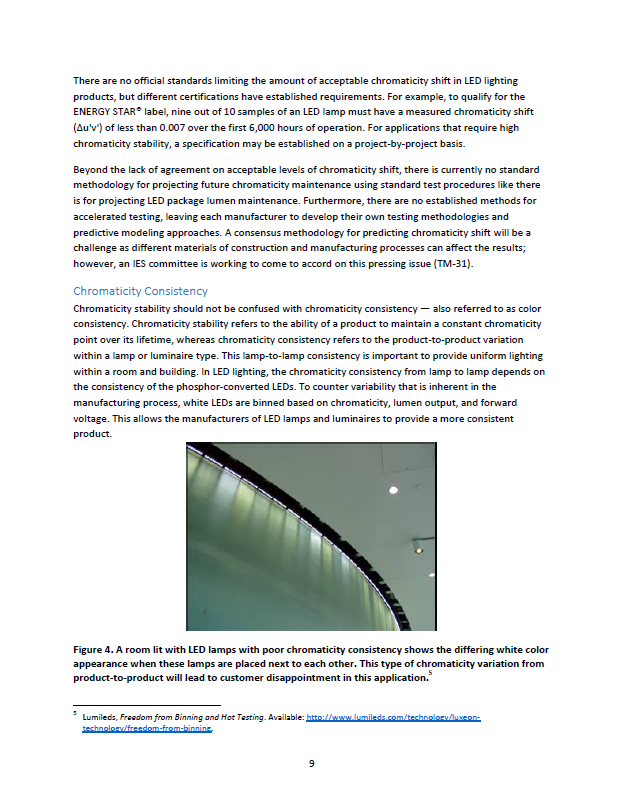

That end user is familiar with basic things about lighting. If 1 of 8 fluorescent troffers doesn't turn on, it's time to replace some lamps -- or perhaps a ballast. If a long row of 5+ year-old metal halide high bay fixtures light up in a rainbow of colors, it's probably time to relamp.

It's well-known that LED light sources don't fail like other light sources. When the tungsten filament breaks in an incandescent lamp, it's time to replace. But when LED fixtures, slowly lose lumen output over many years, the change may be imperceptible to the end user who learns to live with the slowly changing "normal" light levels in the space.

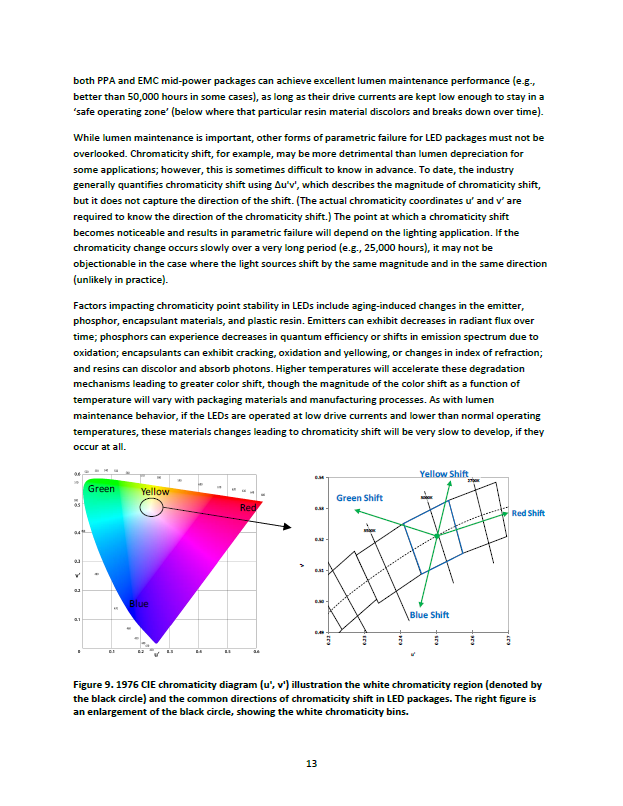

But how will the LED owner of today, and 5-10 years from today, know that the fixtures they are buying will have a sustainable color over time? How can the LED lighting decision maker be sure that the 4000K fixtures they install today don't slowly shift to an undesirable pastel shade of blue, yellow, green or red over time?

How will the LED owners of today, and 5-10 years from today, know that the fixtures they are buying will have a sustainable color over time? How can the LED lighting decision maker be sure that the 4000K fixtures they install today don't slowly shift to an undesirable pastel shade of blue, yellow, green or red over time?

Here is a summary of the recently published report. SOURCE: U.S. Department of Energy

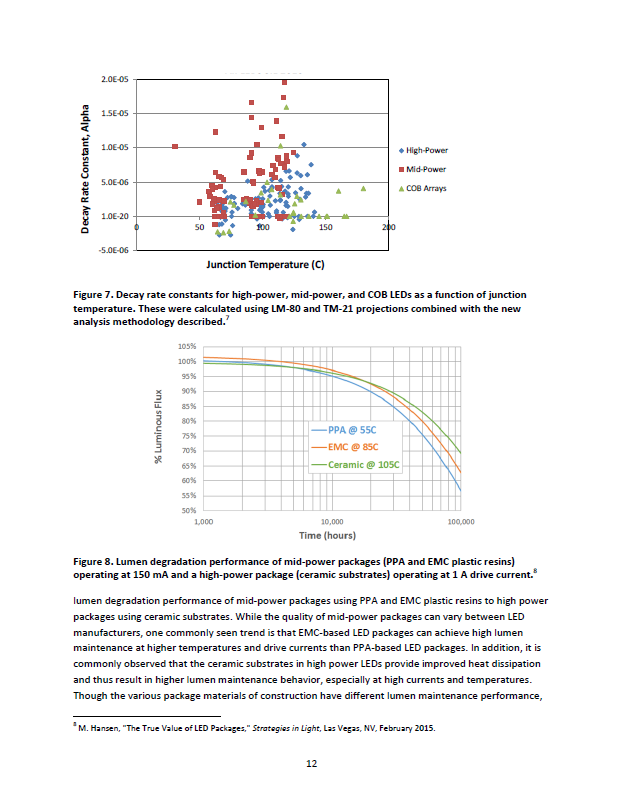

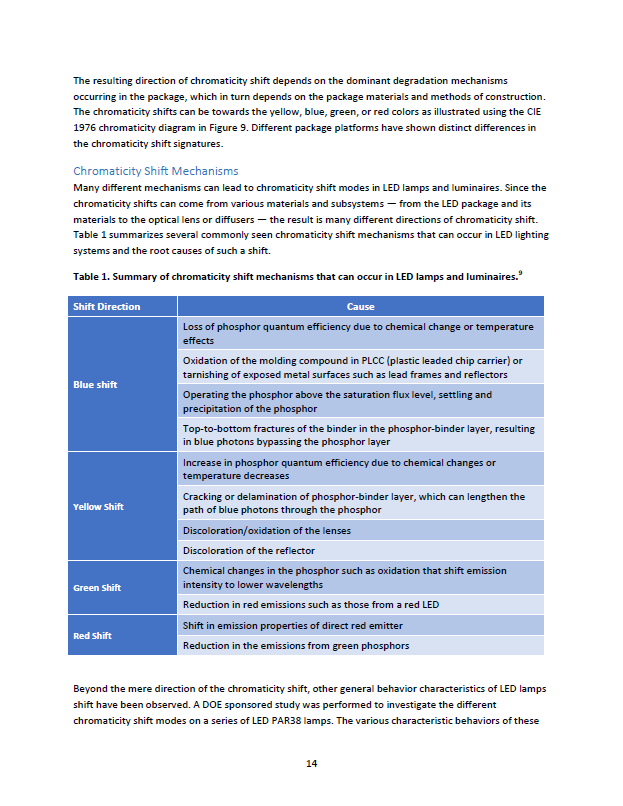

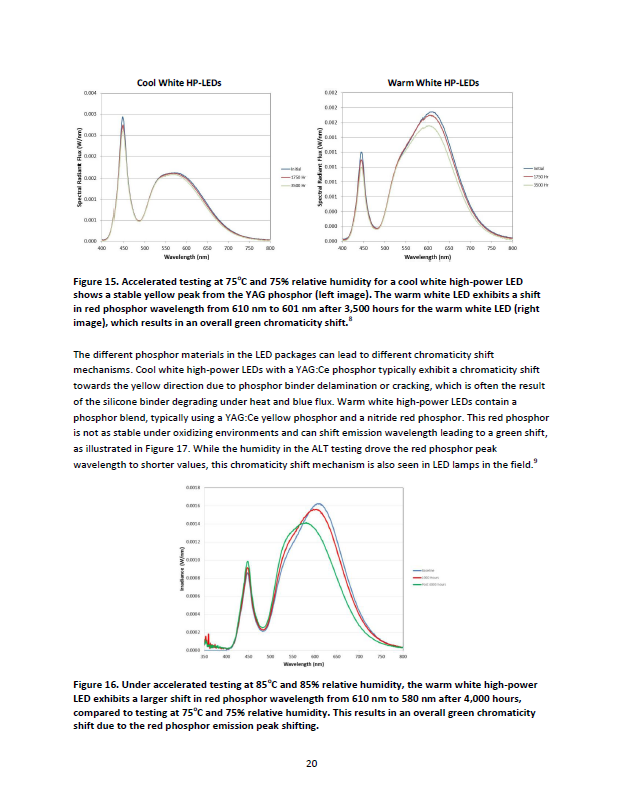

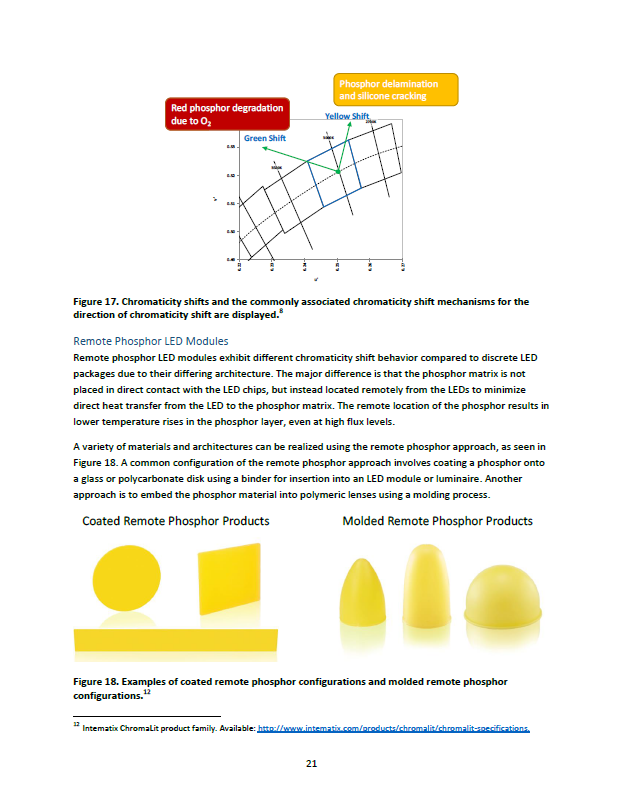

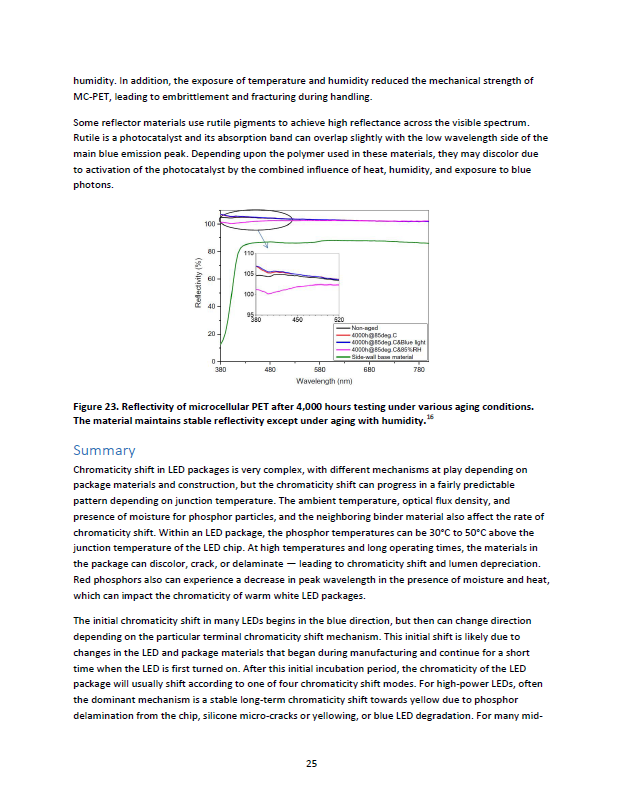

Chromaticity shift in LED packages is very complex, with different mechanisms at play depending on package materials and construction, but the chromaticity shift can progress in a fairly predictable pattern depending on junction temperature. The ambient temperature, optical flux density, and presence of moisture for phosphor particles, and the neighboring binder material also affect the rate of chromaticity shift. Within an LED package, the phosphor temperatures can be 30°C to 50°C above the junction temperature of the LED chip. At high temperatures and long operating times, the materials in the package can discolor, crack, or delaminate — leading to chromaticity shift and lumen depreciation. Red phosphors also can experience a decrease in peak wavelength in the presence of moisture and heat, which can impact the chromaticity of warm white LED packages.

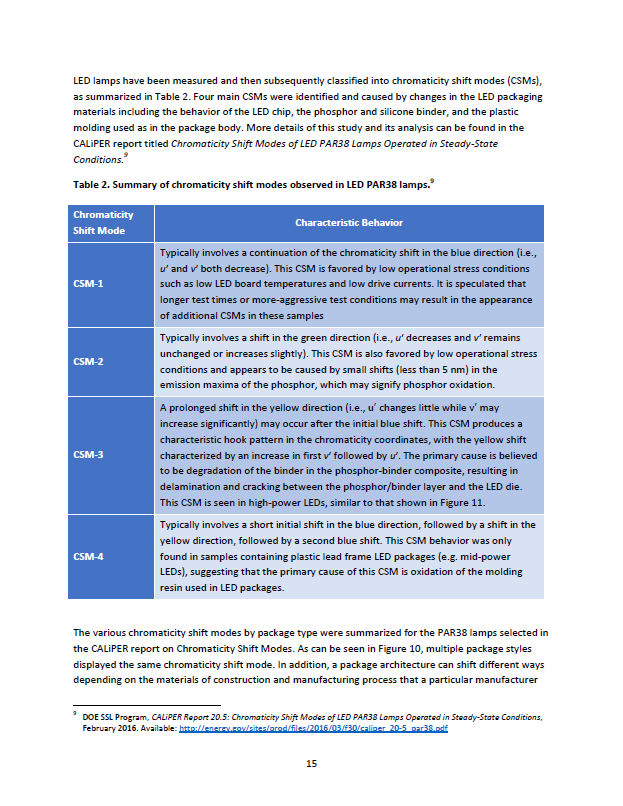

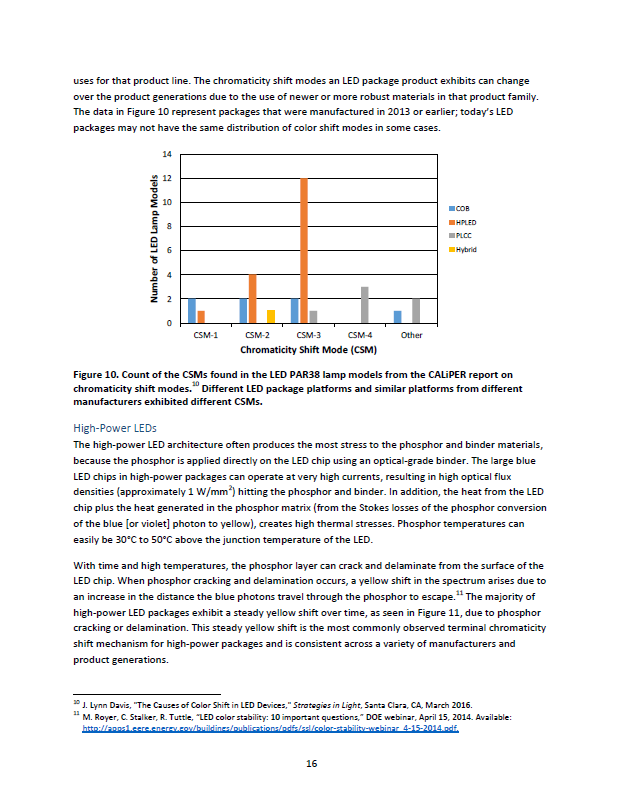

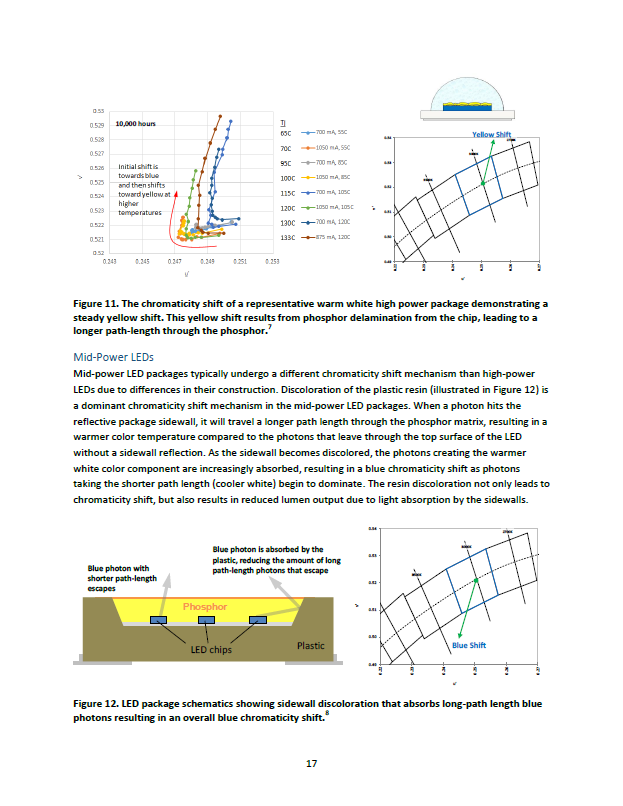

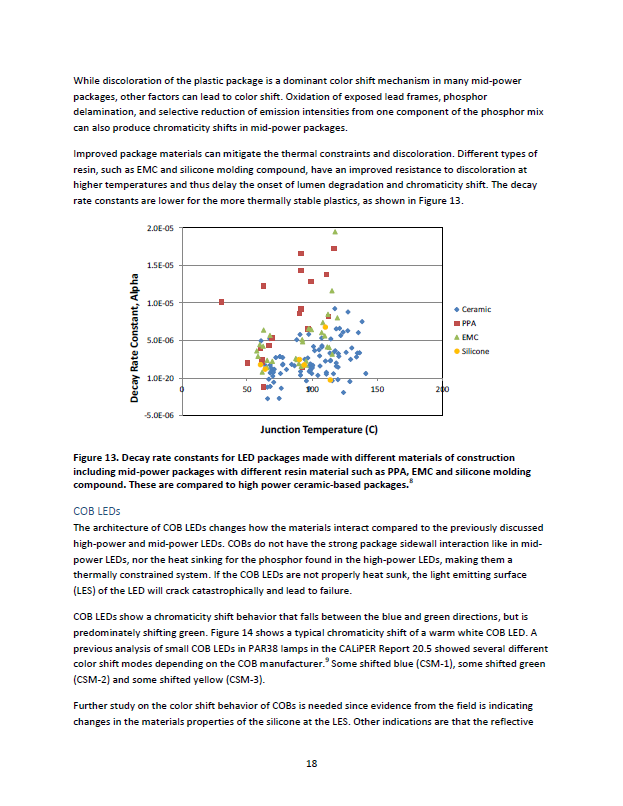

The initial chromaticity shift in many LEDs begins in the blue direction, but then can change direction depending on the particular terminal chromaticity shift mechanism. This initial shift is likely due to changes in the LED and package materials that began during manufacturing and continue for a short time when the LED is first turned on. After this initial incubation period, the chromaticity of the LED package will usually shift according to one of four chromaticity shift modes. For high-power LEDs, often the dominant mechanism is a stable long-term chromaticity shift towards yellow due to phosphor delamination from the chip, silicone micro-cracks or yellowing, or blue LED degradation. For many mid-

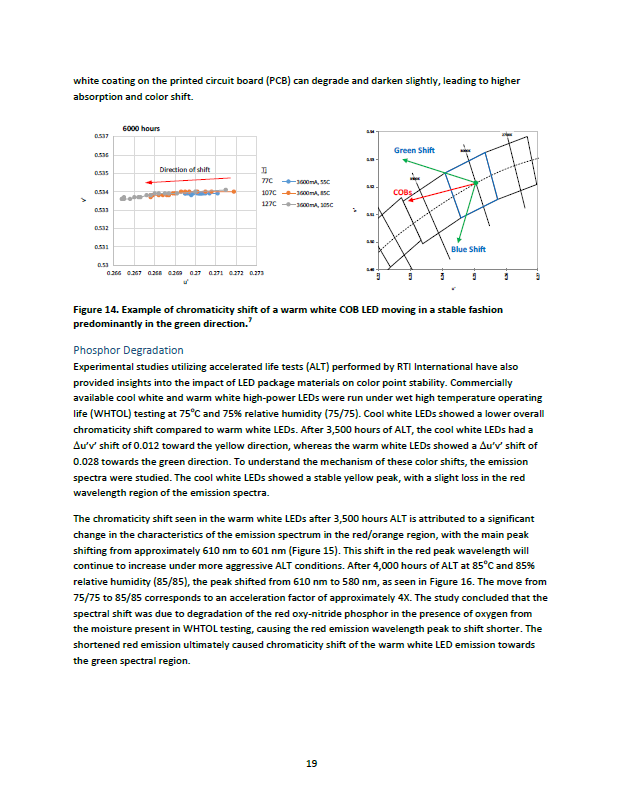

26 power LEDs, the chromaticity shift can move in the blue direction when operated at high temperatures and drive currents due to discoloration of the package resin. Shifts in the green and red directions can also occur in mid-power LEDs depending upon the specifics of the phosphor mix, the LED junction temperature, and the drive current. Improved package resin materials can delay the onset of chromaticity shift due to discoloration. COBs exhibit various chromaticity shifts with a common shift predominantly towards the green direction. The chromaticity shift behavior of COB LEDs is still under investigation for correlation to a physical mechanism. One possibility is discoloration on the white reflective layer of the PCB.

Another area of investigation for LED packages is the new chip scale package (CSP) LED platform. CSP LEDs have gained prominence recently due to their lower cost from minimizing materials and manufacturing steps, as well as their small footprint allowing for tighter packing in a luminaire. The number of CSP product offerings continues to grow, as well as the number of manufacturers offering this LED product type. CSP products are finally starting to reach the 6,000 hour test point for LM-80 reports and analysis can begin on this new LED package platform.

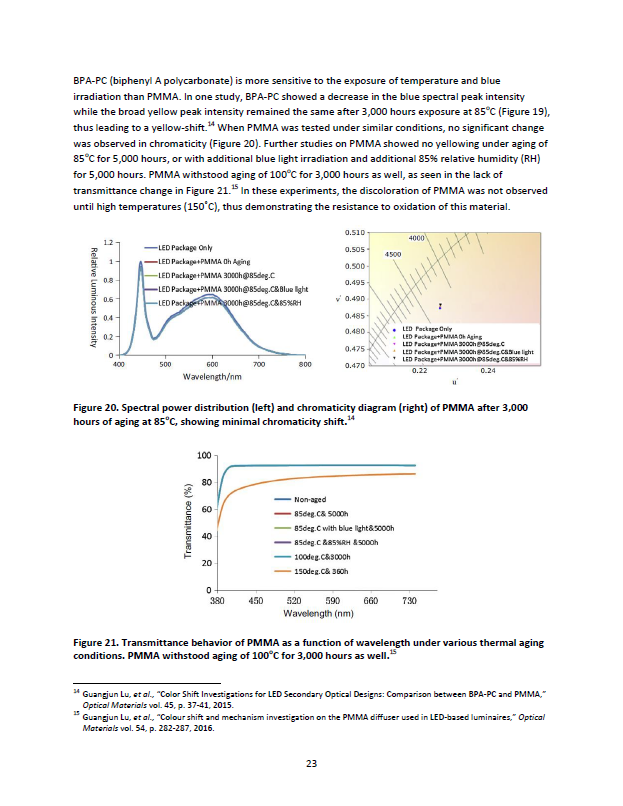

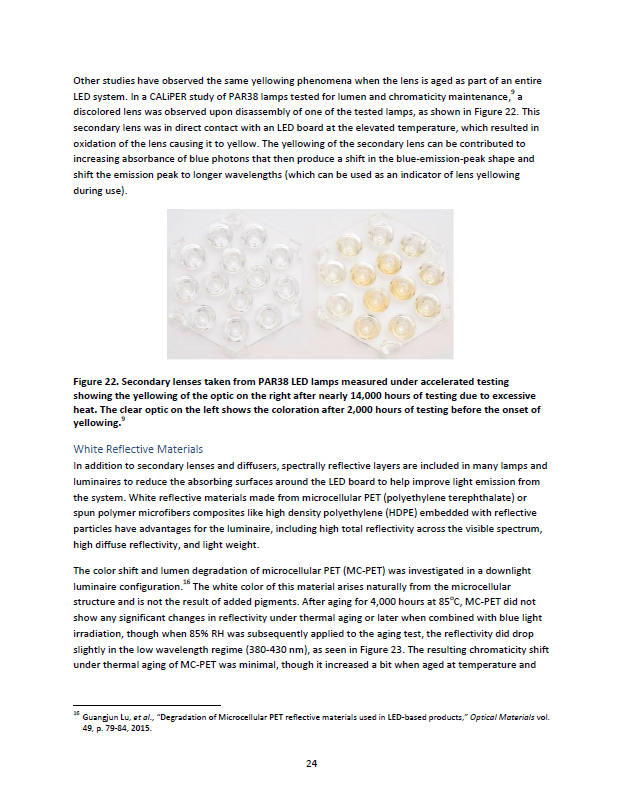

In addition to the chromaticity shift behavior from the LED packages, optical materials in the lamps and luminaires tend to yellow or discolor due to oxidation effects, leading to chromaticity shifts in the yellow direction.

While LED chromaticity shift does occur and can impact the performance of LED lighting products, the new understanding summarized in this paper has allowed the industry to manage the negative impact of such a shift. While LED based lighting can exhibit significantly improved color stability compared to conventional lighting products, their long lifetime requires an understanding of how color might shift over this long life. Further research is needed to develop improved predictive models that will enable manufacturers and consumers to understand the tradeoffs and make informed decisions regarding LED lighting performance requirements and product capabilities.